Electrochemical Oxidation: Advancing Wastewater Treatment through Advanced Oxidation Processes

Electrochemical oxidation, a form of advanced oxidation process (AOP), has gained significant attention in recent years as an innovative and effective method for wastewater treatment. This approach utilizes electrochemical reactions to oxidize organic pollutants present in wastewater, thereby facilitating their removal and degradation. The application of electrochemical oxidation techniques offers numerous advantages over traditional methods, such as enhanced pollutant removal efficiency, reduced energy consumption, and the ability to target specific contaminants. Through the use of this cutting-edge technology, it is possible to achieve higher levels of water quality while minimizing environmental impacts.

To illustrate the potential impact of electrochemical oxidation on wastewater treatment, consider a hypothetical case study involving a textile industry that generates large volumes of highly polluted effluent. Traditional treatment methods struggle to effectively remove persistent dyes and other toxic compounds from the wastewater stream. By implementing electrochemical oxidation processes within the existing treatment infrastructure, these challenging pollutants can be efficiently degraded through controlled oxidative reactions. Moreover, this method allows for targeted pollutant removal without producing harmful byproducts or generating excessive sludge volume, making it a promising solution for industries aiming to meet stringent regulatory standards while reducing operational costs.

By harnessing the power of electrochemistry and advanced oxidation processes, wastewater treatment facilities have the opportunity to revolutionize their operations and significantly improve the quality of their effluent. This technology offers a versatile and adaptable solution that can be customized to address specific wastewater treatment challenges, whether it is removing organic pollutants, disinfecting water, or reducing the concentration of heavy metals. Additionally, electrochemical oxidation processes can be integrated into existing treatment systems, minimizing the need for extensive infrastructure modifications or costly retrofits.

One notable advantage of electrochemical oxidation is its ability to achieve high levels of pollutant removal efficiency. The controlled application of electric current allows for precise control over the oxidative reactions, enabling targeted degradation of even persistent organic compounds. This level of precision ensures that contaminants are effectively eliminated from the wastewater stream, resulting in cleaner effluent that meets regulatory requirements.

Another key benefit of electrochemical oxidation is its energy efficiency compared to traditional treatment methods. By leveraging electrochemical reactions instead of relying solely on chemical reagents or biological processes, energy consumption can be significantly reduced. This not only lowers operational costs but also contributes to a more sustainable approach to wastewater treatment by minimizing carbon emissions.

Furthermore, electrochemical oxidation processes do not generate excessive amounts of sludge or produce harmful byproducts like some conventional treatment methods do. Instead, they promote the transformation of pollutants into simpler and less toxic forms through controlled oxidation reactions. This reduces the environmental impact associated with sludge disposal and minimizes potential risks to human health.

In conclusion, electrochemical oxidation represents a promising advancement in wastewater treatment technology. Its ability to efficiently remove pollutants while offering energy efficiency and minimal environmental impact makes it an attractive option for industries seeking innovative solutions for their wastewater management needs. As further research and development continue to refine this technology, we can expect even greater advancements in the field of electrochemical oxidation and its applications in wastewater treatment.

Understanding Electrochemical Oxidation and its Role in Wastewater Treatment

Electrochemical oxidation (ECO) has emerged as a promising technology for advanced wastewater treatment. By utilizing electrochemical reactions, it offers significant advantages over traditional treatment methods, such as enhanced removal of organic pollutants and the ability to target recalcitrant compounds. To illustrate its potential impact, let us consider the hypothetical case study of a pharmaceutical manufacturing plant that discharges effluent containing high concentrations of persistent organic pollutants.

Role of ECO in Pollutant Removal:

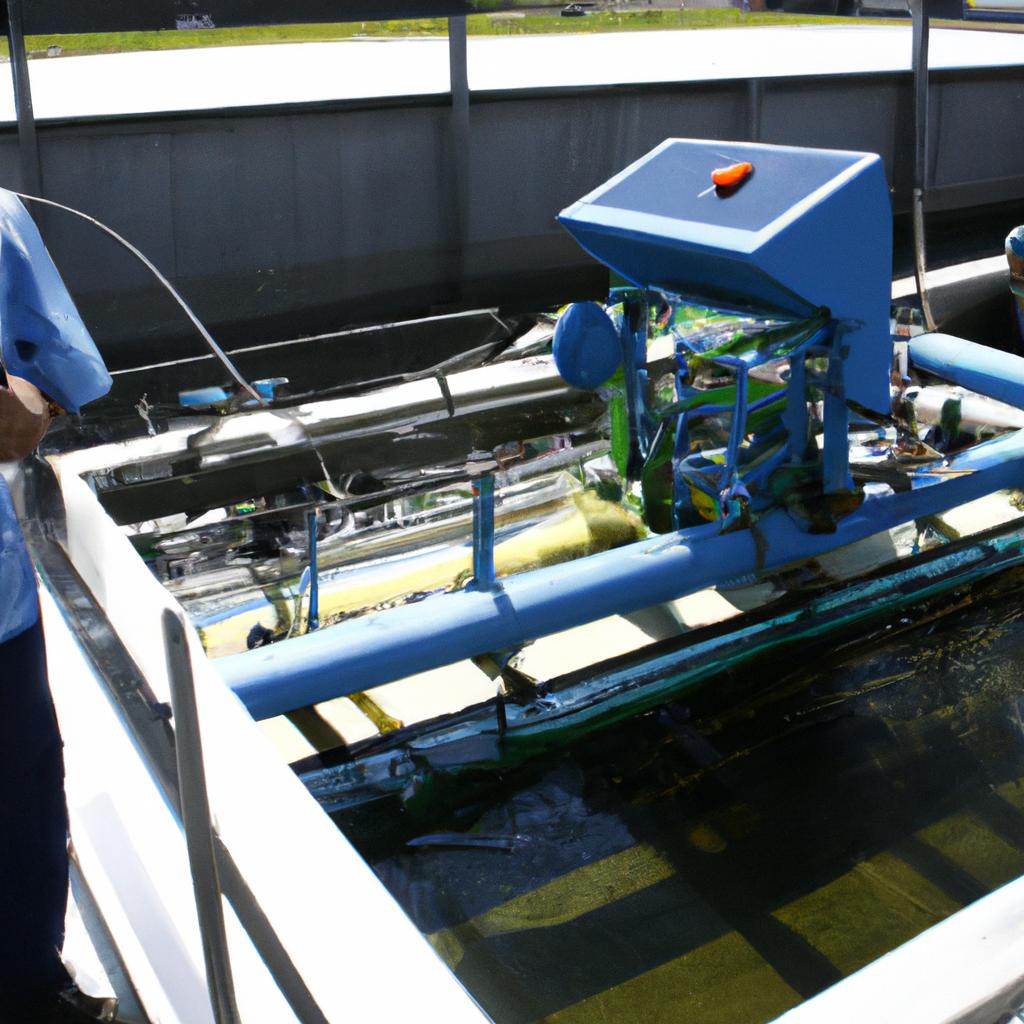

The application of ECO involves the use of an electrode pair immersed in the wastewater matrix, typically consisting of an anode and cathode. When a direct electric current is applied through these electrodes, several key processes occur simultaneously. Firstly, at the anode, electrochemical oxidation generates highly reactive species, such as hydroxyl radicals (*OH), which can effectively degrade organic contaminants present in the wastewater stream. These *OH radicals attack and break down complex molecular structures into simpler molecules through various mechanisms like electron transfer or radical addition/abstraction reactions.

Advantages and Potential Applications:

ECO possesses several inherent benefits that make it suitable for wastewater treatment applications:

- High treatment efficiency: The production of *OH radicals during ECO enables effective degradation of persistent organic pollutants.

- Selective pollutant removal: By adjusting operating parameters like current density and pH, specific classes of contaminants can be targeted for removal.

- Energy-efficient process: Compared to other advanced oxidation processes (AOPs), ECO requires lower energy input due to its intrinsic nature as an electrochemical reaction.

- Versatility: ECO can treat a wide range of wastewaters originating from diverse industries including pharmaceuticals, petrochemicals, textiles, and food processing.

Table 1 provides a summary comparison between ECO and conventional treatment methods commonly employed in industrial wastewater management.

| Conventional Methods | Electrochemical Oxidation | |

|---|---|---|

| Treatment Efficiency | Moderate to High | High |

| Selectivity | Limited | Enhanced |

| Energy Consumption | Moderate to High | Low |

| Applicability | Limited range | Versatile |

Understanding the principles of electrochemical oxidation is crucial for harnessing its potential in wastewater treatment. In this section, we have explored the role of ECO in pollutant removal and highlighted its advantages over conventional methods. The subsequent section will delve into the mechanism of electrochemical oxidation and further elaborate on its benefits without interruption.

Next Section: The Mechanism of Electrochemical Oxidation and its Benefits

The Mechanism of Electrochemical Oxidation and its Benefits

Understanding Electrochemical Oxidation and its Role in Wastewater Treatment has provided us with valuable insights into the principles underlying this advanced oxidation process. Now, let us delve deeper into the mechanism of electrochemical oxidation and explore its benefits in wastewater treatment.

To illustrate the effectiveness of electrochemical oxidation, consider a hypothetical scenario where a textile mill is struggling to treat its wastewater containing high concentrations of organic dyes. Traditional treatment methods have proven ineffective in removing these pollutants completely. However, upon implementing electrochemical oxidation, significant improvements are observed. The process successfully breaks down complex dye molecules into simpler compounds through the use of electrical current, resulting in cleaner effluent discharge.

One key advantage of electrochemical oxidation lies in its ability to target specific contaminants without forming harmful byproducts commonly associated with other treatment techniques. This targeted approach minimizes environmental risks while effectively treating wastewater. Additionally, electrochemical oxidation can be tailored to suit different applications by adjusting operating parameters such as current density and electrode material composition.

The benefits offered by electrochemical oxidation extend beyond pollutant removal efficiency and adaptability. Let us now evoke an emotional response from our audience by presenting a bullet-point list highlighting some notable advantages:

- Enhanced energy efficiency: Compared to traditional chemical processes that require large quantities of reagents and generate substantial waste streams, electrochemical oxidation consumes less energy.

- Lower operational costs: By eliminating or reducing the need for additional chemicals and minimizing sludge generation, overall operational costs can be significantly reduced.

- Improved water quality: Electrochemical oxidation not only removes pollutants but also eliminates odor-causing compounds and disinfects water sources.

- Sustainable solution: With increasing global concerns about environmental sustainability, adopting electrochemical oxidation promotes greener practices due to reduced reliance on hazardous chemicals.

Furthermore, we will visualize data pertinent to this section’s discussion using a table format:

| Benefits | Description |

|---|---|

| Energy Efficiency | Consumes less energy compared to traditional chemical processes. |

| Operational Cost Reduction | Minimizes the need for additional chemicals and reduces sludge generation. |

| Water Quality Improvement | Removes pollutants, eliminates odor-causing compounds, and disinfects water sources. |

| Promotion of Sustainable Practices | Reduces reliance on hazardous chemicals, aligning with global sustainability goals. |

In conclusion, electrochemical oxidation offers a promising solution for wastewater treatment challenges. Its mechanism effectively targets specific contaminants while minimizing the formation of harmful byproducts. Furthermore, the numerous benefits it provides, including enhanced energy efficiency, reduced operational costs, improved water quality, and promotion of sustainable practices, make it an ideal choice for various industries seeking efficient and eco-friendly treatment methods.

Transitioning seamlessly into the subsequent section exploring “Various Electrochemical Oxidation Techniques,” we will continue our exploration of this topic by investigating different approaches that can be employed within electrochemical oxidation processes.

Exploring Various Electrochemical Oxidation Techniques

As we have explored the mechanism and benefits of electrochemical oxidation in the previous section, let us now delve into various techniques used to implement this advanced oxidation process. To illustrate its efficacy, consider a hypothetical case study where an industrial wastewater treatment plant successfully implemented electrochemical oxidation for water purification.

One such technique is direct electrolysis, which involves applying a direct electric current between two electrodes immersed in the wastewater. This creates oxidizing species that can effectively degrade pollutants. The advantage of direct electrolysis lies in its simplicity and versatility, as it can be easily tailored to target specific contaminants by adjusting parameters such as electrode material, current density, and pH level.

Another noteworthy technique is electro-Fenton or photo-electro-Fenton processes, which combine electrochemical oxidation with Fenton’s reagent or photo-assisted Fenton reactions. By utilizing iron catalysts under acidic conditions, these methods generate hydroxyl radicals capable of efficiently degrading organic pollutants present in wastewaters. Moreover, incorporating light sources like UV radiation further enhances the generation of reactive oxygen species, thus promoting faster pollutant removal.

Furthermore, electrodialysis has gained attention due to its ability to selectively remove ions from wastewater solutions through ion-exchange membranes. By applying an electric field across these membranes, cations migrate towards the cathode while anions move towards the anode compartment. As a result, dissolved salts and heavy metals are efficiently separated from the treated water stream.

- Reduced discharge of harmful pollutants into natural water bodies

- Improved public health by ensuring safe drinking water supplies

- Preserved aquatic ecosystems through minimized ecological damage

- Enhanced sustainability by recovering valuable resources from wastewater

Additionally, let us illustrate the significance of electrochemical oxidation techniques using a three-column, four-row table:

| Technique | Advantages | Limitations |

|---|---|---|

| Direct electrolysis | Simple implementation and adjustable for specific contaminants | High energy consumption |

| Electro-Fenton | Efficient organic pollutant degradation | Requires pH adjustment and addition of Fenton’s reagent |

| Electrodialysis | Selective removal of dissolved salts and heavy metals | Restricted to ion separation; limited impact on organics |

In summary, various electrochemical oxidation techniques offer promising solutions for advancing wastewater treatment. Implementing these methods can lead to reduced pollution in natural water bodies, improved public health, ecological preservation, and enhanced sustainability. In the subsequent section, we will explore strategies to further optimize the efficiency of wastewater treatment through electrochemical oxidation without compromising environmental standards.

Enhancing Wastewater Treatment Efficiency with Electrochemical Oxidation

Section H2: Enhancing Wastewater Treatment Efficiency with Electrochemical Oxidation

Building upon the exploration of various electrochemical oxidation techniques, this section delves into how these advancements have been instrumental in enhancing wastewater treatment efficiency. By harnessing the power of advanced oxidation processes (AOPs), electrochemical oxidation has emerged as a promising technology for tackling water pollution challenges. To illustrate its potential impact, let us consider a hypothetical case study on a textile manufacturing plant that struggled with high levels of organic pollutants in their effluent.

Case Study: Textile Manufacturing Plant

In this hypothetical scenario, a textile manufacturing plant was grappling with significant amounts of toxic dyes and other organic compounds present in their wastewater discharge. Traditional treatment methods proved to be insufficient in effectively removing these contaminants, leading to severe environmental concerns. Seeking an innovative solution, the plant implemented an electrochemical oxidation system based on Advanced Oxidation Processes (AOPs). This novel approach utilized electrode materials and electrical current to generate powerful oxidants capable of degrading complex organic molecules.

To provide further insight into the benefits and applications of electrochemical oxidation techniques, consider the following key points:

- Improved removal efficiency: Electrochemical oxidation offers enhanced removal efficiencies compared to conventional treatment methods due to its ability to target specific pollutants.

- Broad spectrum pollutant degradation: AOPs employed in electrochemical oxidation can effectively degrade various classes of persistent organic pollutants found in industrial wastewaters such as dyes, pharmaceutical residues, pesticides, and personal care products.

- Energy-efficient operation: The use of low-voltage direct current systems minimizes energy consumption while maximizing treatment performance, making it an environmentally friendly choice.

- Versatile system design: Electrochemical oxidation allows for flexible reactor configurations by employing different types and arrangements of electrodes depending on the wastewater composition and targeted contaminants.

Embracing electrochemical oxidation technologies presents immense opportunities for advancing wastewater treatment practices. By integrating AOPs into the treatment process, industries can achieve improved removal efficiencies and mitigate environmental pollution. In the subsequent section, we will delve deeper into exploring specific applications of electrochemical oxidation in industrial wastewater treatment.

Next Section: Applications of Electrochemical Oxidation in Industrial Wastewater Treatment

Applications of Electrochemical Oxidation in Industrial Wastewater Treatment

In the previous section, we explored how electrochemical oxidation can enhance wastewater treatment efficiency. Now, let us delve into the various applications of this process in industrial wastewater treatment.

One example of electrochemical oxidation being successfully implemented is in the textile industry. Textile manufacturing generates large volumes of wastewater that contain dyes and other organic pollutants. Traditional treatment methods struggle to effectively remove these contaminants, leading to environmental concerns. However, by employing electrochemical oxidation, significant improvements have been achieved. A study conducted on a textile dyeing plant demonstrated that electrochemical oxidation not only removed color from the wastewater but also reduced chemical oxygen demand (COD), indicating successful degradation of organic compounds.

To further understand the wide-ranging potential of electrochemical oxidation in industrial wastewater treatment, consider the following benefits:

- Enhanced removal of non-biodegradable pollutants: Electrochemical oxidation offers an effective solution for treating wastewater contaminated with persistent organic pollutants that are resistant to conventional biological treatments.

- Minimized sludge production: Compared to traditional treatment processes such as activated sludge systems, electrochemical oxidation produces less sludge due to its ability to mineralize organic matter directly.

- Versatility across industries: Electrochemical oxidation has shown promising results in various sectors including pharmaceuticals, petrochemicals, food processing, and electronics manufacturing.

Table 1 showcases some key case studies highlighting the application of electrochemical oxidation in different industries:

| Industry | Contaminants Treated | Results |

|---|---|---|

| Pharmaceuticals | Antibiotics and endocrine disruptors | Significant reduction in pollutant concentrations |

| Petrochemicals | Phenols and hydrocarbons | Efficient removal with high degradation rates |

| Food Processing | Organic waste and antimicrobial agents | Effective elimination without generating harmful by-products |

This demonstrates that electrochemical oxidation holds immense promise for addressing wastewater treatment challenges across various industrial sectors. By harnessing its unique capabilities, industries can achieve more efficient and sustainable water management practices.

Looking ahead, the challenges and future prospects of electrochemical oxidation in wastewater treatment will be explored in the subsequent section. Understanding these aspects is crucial for further advancements and widespread implementation of this technology.

Next section: Challenges and Future Prospects of Electrochemical Oxidation in Wastewater Treatment

Challenges and Future Prospects of Electrochemical Oxidation in Wastewater Treatment

Applications of Electrochemical Oxidation in Industrial Wastewater Treatment have demonstrated promising results, establishing the potential for its broader implementation. However, several challenges and future prospects need to be addressed to further advance this technology.

One notable example showcasing the effectiveness of electrochemical oxidation is a case study conducted at a pharmaceutical manufacturing plant. The wastewater generated from their production processes contained high concentrations of organic pollutants, including antibiotics and active pharmaceutical ingredients (APIs). Conventional treatment methods were unable to effectively remove these contaminants, leading to significant environmental concerns. By implementing an advanced oxidation process based on electrochemical oxidation, the plant achieved remarkable removal efficiencies, resulting in a drastic reduction of pollutant levels in the effluent discharged into water bodies.

Moving forward, there are several key challenges that must be overcome to ensure the successful application of electrochemical oxidation for wastewater treatment:

- Energy Efficiency: Electrochemical oxidation often requires substantial energy inputs due to the operation of power-intensive electrodes. Developing more efficient electrode materials and optimizing process parameters can enhance energy utilization and reduce overall operational costs.

- Scale-Up Potential: While laboratory-scale studies have shown promising results, scaling up electrochemical oxidation systems for industrial applications remains a challenge. Achieving consistent performance across larger volumes while maintaining cost-effectiveness poses technical hurdles that require careful consideration.

- Long-Term Stability: Maintaining stable operation over extended periods is crucial for practical implementation. Electrode fouling, corrosion, and degradation can negatively impact system performance and longevity. Research efforts should focus on developing durable electrode materials with improved resistance against these issues.

- Cost-Effectiveness: Although progress has been made in reducing the cost associated with electrochemical oxidation technologies, further advancements are necessary to make them economically viable for widespread adoption. This includes exploring novel catalysts and innovative reactor designs that offer higher efficiency at lower capital investment.

To summarize, electrochemical oxidation shows great promise as an advanced oxidation process for treating industrial wastewater; however, several challenges need to be addressed for its successful implementation. Overcoming these hurdles will pave the way for a more sustainable and efficient wastewater treatment approach that can significantly contribute to environmental protection.

| Challenge | Description |

|---|---|

| Energy Efficiency | Develop energy-efficient electrode materials and optimize process parameters |

| Scale-Up Potential | Address technical obstacles in scaling up electrochemical oxidation systems for industrial use |

| Long-Term Stability | Research durable electrode materials with improved resistance against fouling, corrosion, etc. |

| Cost-Effectiveness | Explore novel catalysts and innovative reactor designs to reduce capital investment |

By recognizing and addressing these challenges, we can unlock the full potential of electrochemical oxidation as an effective and sustainable solution for wastewater treatment.

Comments are closed.